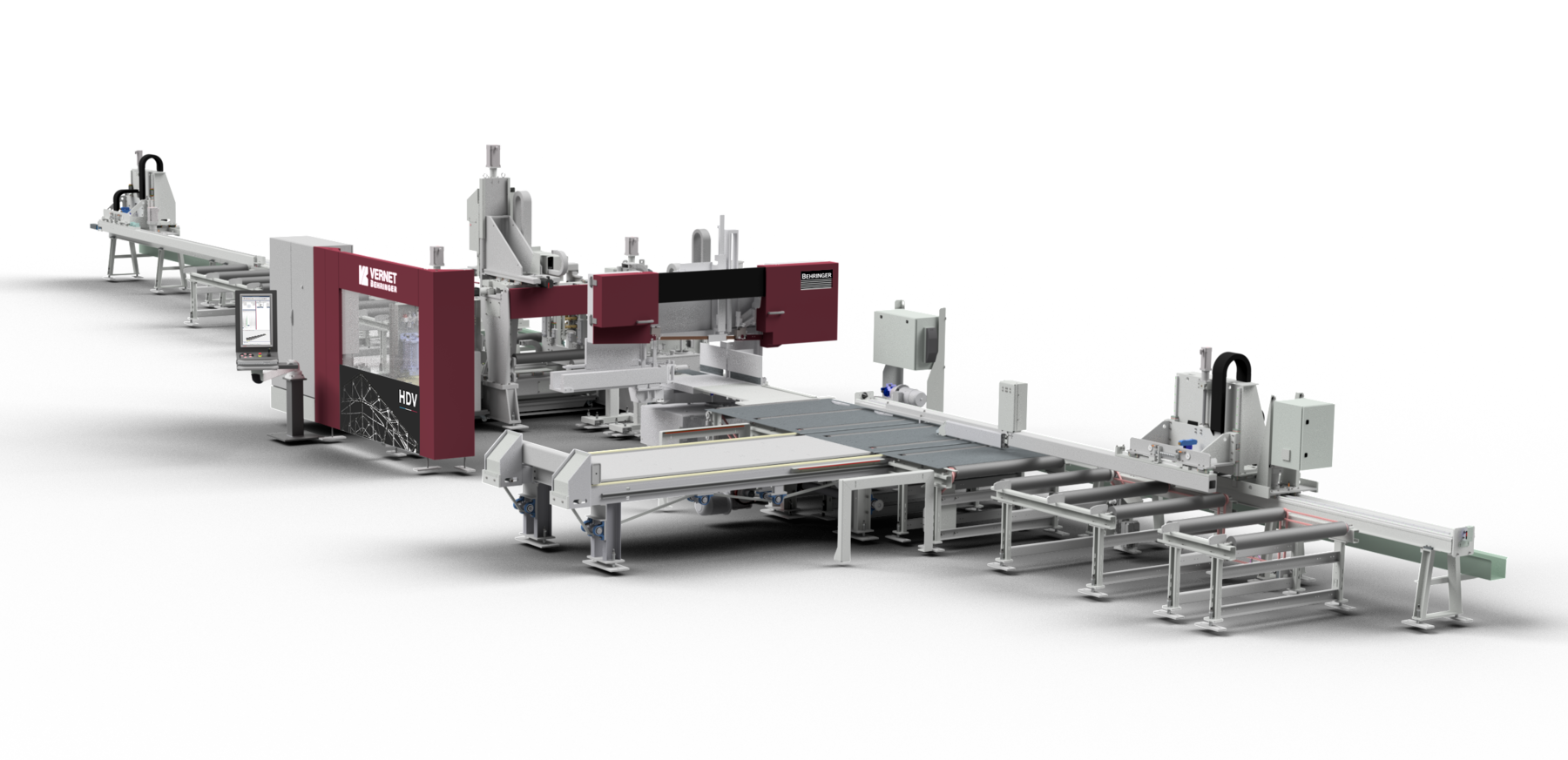

At the Schweissen & Schneiden 2025 international trade fair, we will be exclusively presenting our brand new HDV machine, designed for marking, drilling and milling steel profiles. Designed to combine compactness, performance and versatility, the HDV offers all the advantages of the HDX in a format that is optimised to fit perfectly into your workshops.

Extensive customisation to meet your requirements

As your production is unique, Vernet Behringer offers a range of customisation options to adapt the HDV to your specific requirements. :

- Machining on all 4 sides

- Flow Drilling

- Machining of profiles for Jansen-type steel profiles

These possibilities enable you, as steel constructors, locksmiths and service centres, to gain flexibility and competitiveness, while meeting the most demanding requirements of your market.

An eco-designed and connected machine

Despite having half the installed power of competing machines, the HDV boasts remarkable energy efficiency without compromising on performance. It is controlled by our PRONC3 software suite, which facilitates multi-format import, intelligent stock management, advanced nesting, and production tracking.

A complete range for steel specialists

Presented in line with the Behringer mitre bandsaw HBE320-523G saw, the HDV forms a complete solution for steel fabricators, locksmiths and service centres. With 60° rotation on both sides, cutting pressure control and servo-motorised feed, this saw guarantees versatility, precision and low running costs.

Automatisation & P4S

Vernet Behringer lines can be configured with automated loading, conveying and unloading systems, enabling operator-free production during the night. Thanks to our partnership with Rösler, they can be integrated into shot blasting and painting lines to ensure maximum productivity.