|

Events

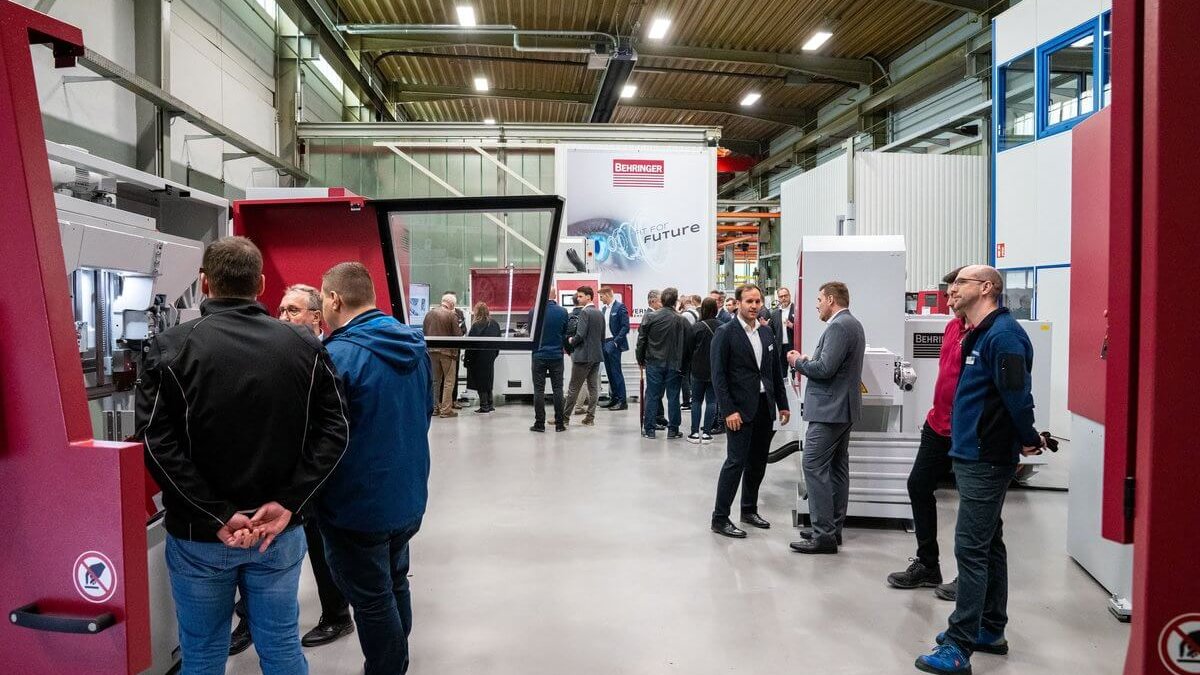

Steeldays – Open House of the Behringer Group

The Behringer in-house exhibition "Steeldays 2023" provided impetus for…

|

Company

Family succession at BEHRINGER

On December 31, 2022, Rolf Behringer will retire from the management. He…

|

Applications

Stahlbau Westerwald relies on a MAGevo 620

The plate processing centre from Vernet Behringer has been supporting the…