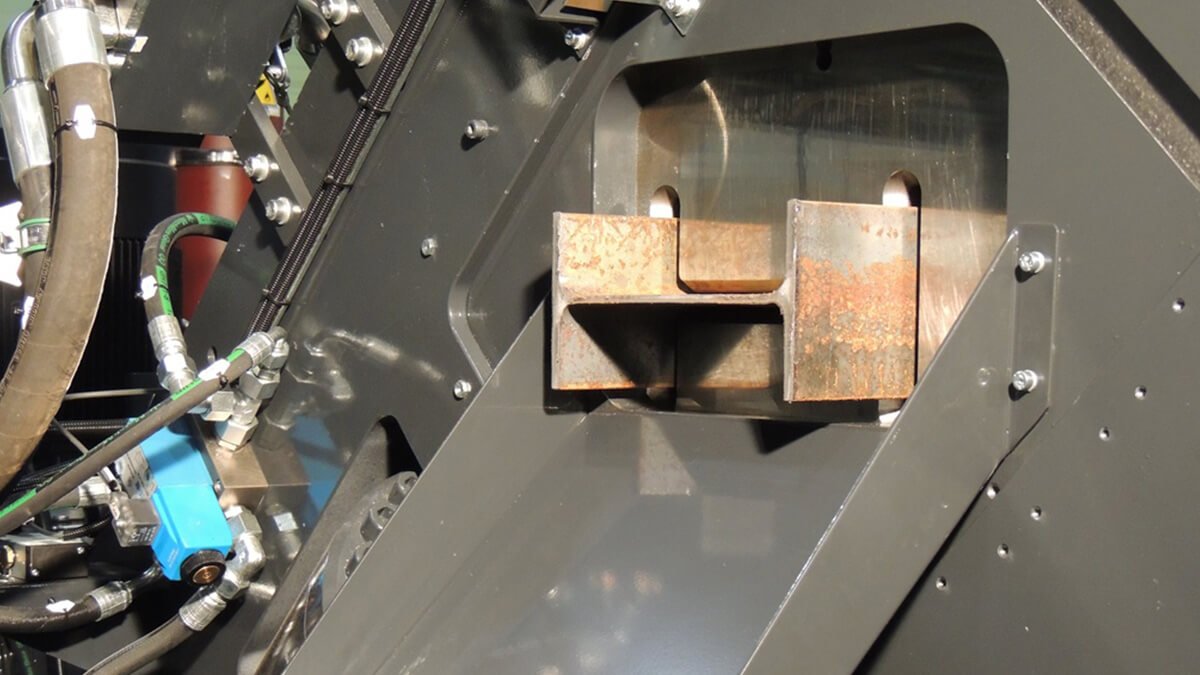

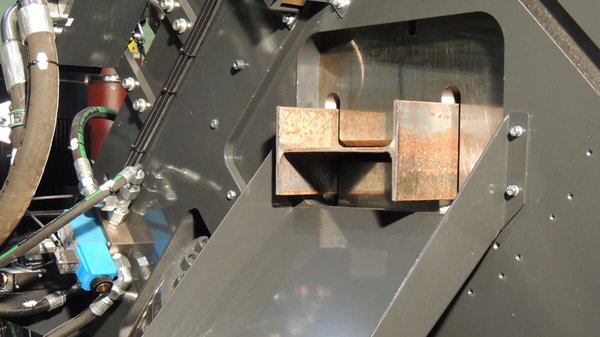

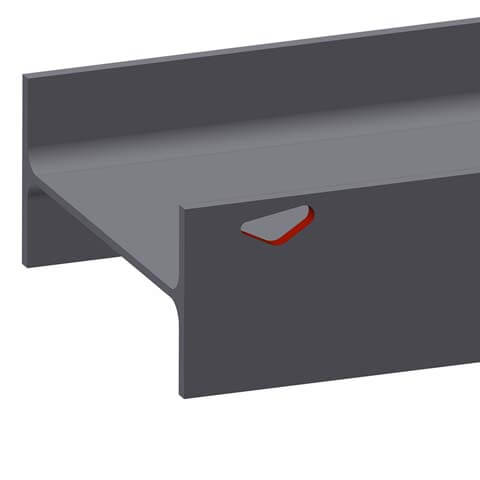

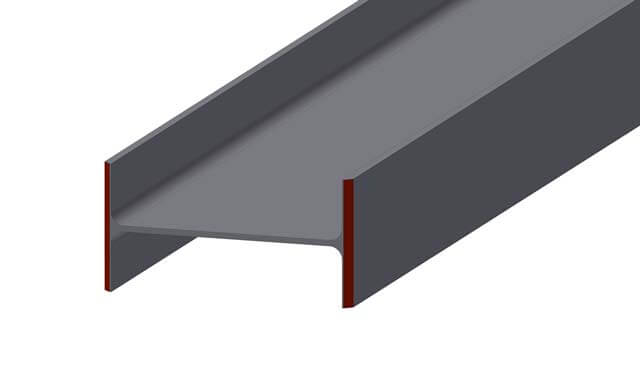

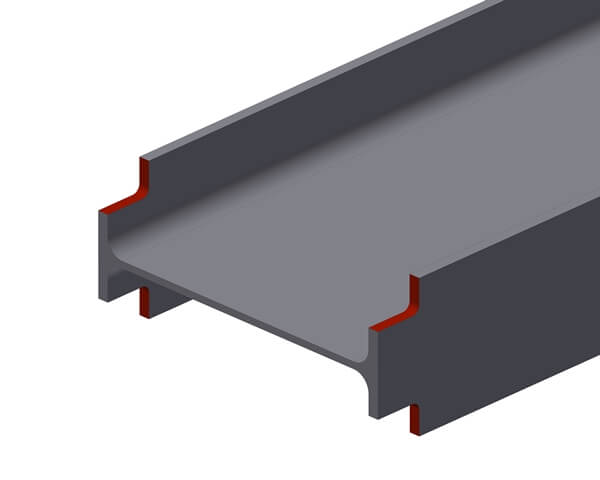

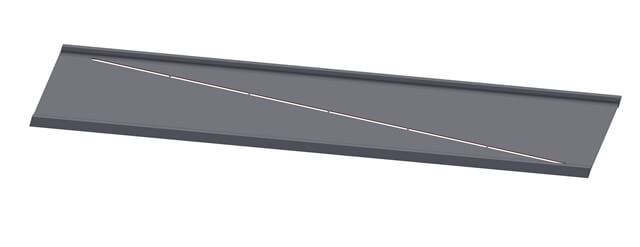

The HDX machining centre from Vernet Behringer is the fastest drilling, milling and marking machine on the market. Thanks to its 3 independent machining spindles, H, U and angle profiles as well as flat steel and rectangular tubes can be machined on 3 sides simultaneously. It is even possible to add one more milling spindle to process sections on 4 sides.

The HDX profile machining centers can be combined with bandsaws and/or shearing units. These universal lines offer great flexibility combined with very high productivity.

- Reduce your power consumption

Energy-saving design with high efficiency spindle motors & servo-driven hydraulic unit

- Increase your production capacity

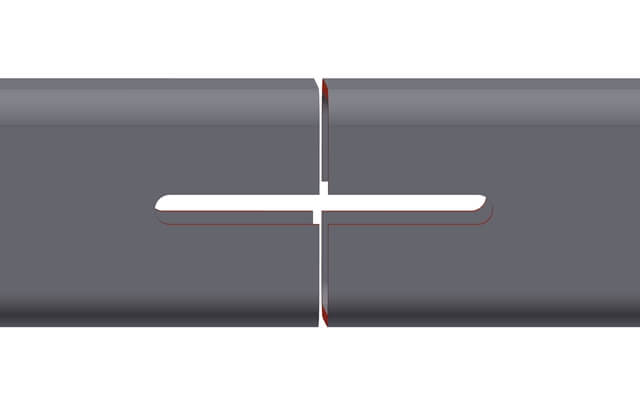

Up to 60% faster than a traditional drilling machine thanks to the additional X-stroke of 500 mm on the 3 drilling units: thus, simultaneous drilling is possible on the flanges and in the web at different positions, as well as machining in hidden time during sawing (according to part drawings). Spindle speed up to 4000 rpm combined with high torque for high performance carbide drilling up to 50 mm diameter.

- Monitor your production

User-friendly and powerful software suite allowing the optimization of your bar stock, the import and easy programming of your parts, the addition of information on your parts such as coding and slinging indications, manage and optimize your scrap stock. Make your machine communicate with your ERP.

| Feeding system | CNC high speed carriage with hydraulic gripper |

| Spindles | 3 spindles with 500 mm stroke in X-axis |

| V-scoring fast scribing | |

| Milling | Standard |

| Threading | Standard |

| Spindle power (S6-60 %) | 16 kW |

| Spindle speed | 160 – 4,000 rpm |

| Max. drilling diameter | 50 mm Ø |

| Tool changers | 10 / 12 / 10 positions |

| Control system | PRONC23D user-friendly programming software with 3D part display |