Steeldays – Open House of the Behringer Group

The Behringer in-house exhibition "Steeldays 2023" provided impetus for innovative production processes

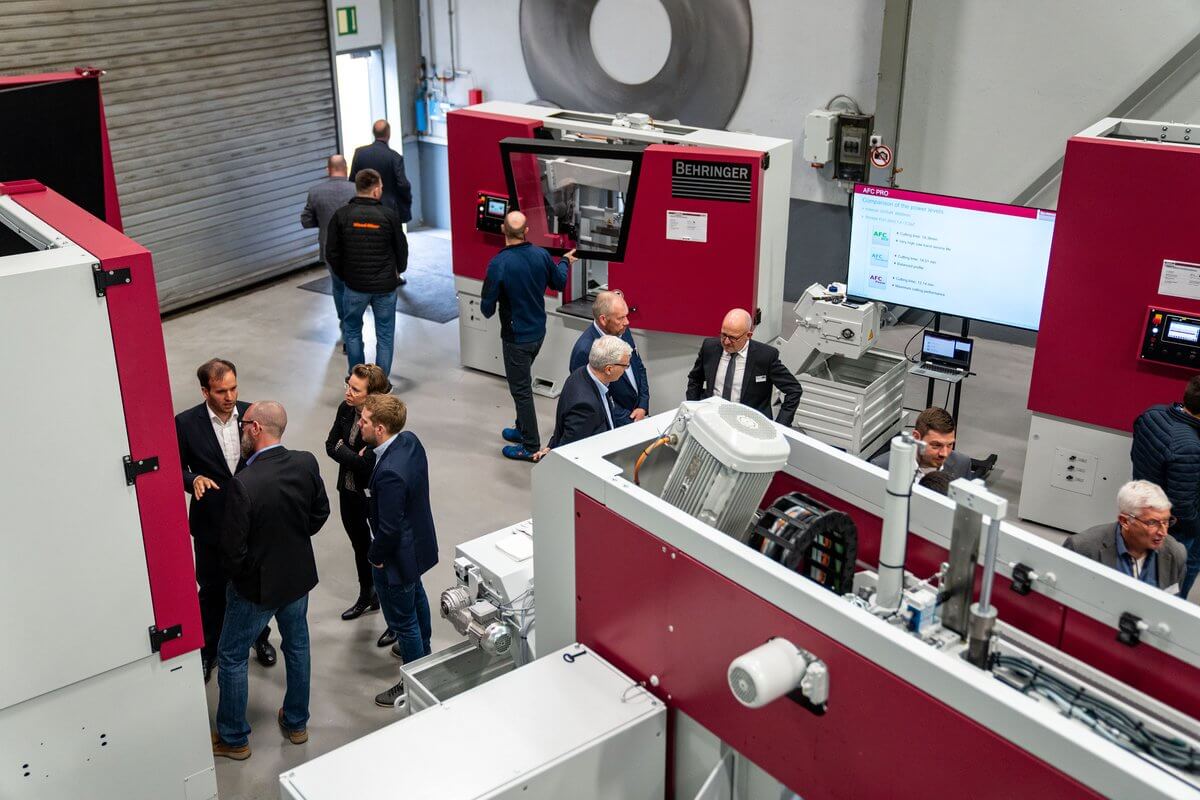

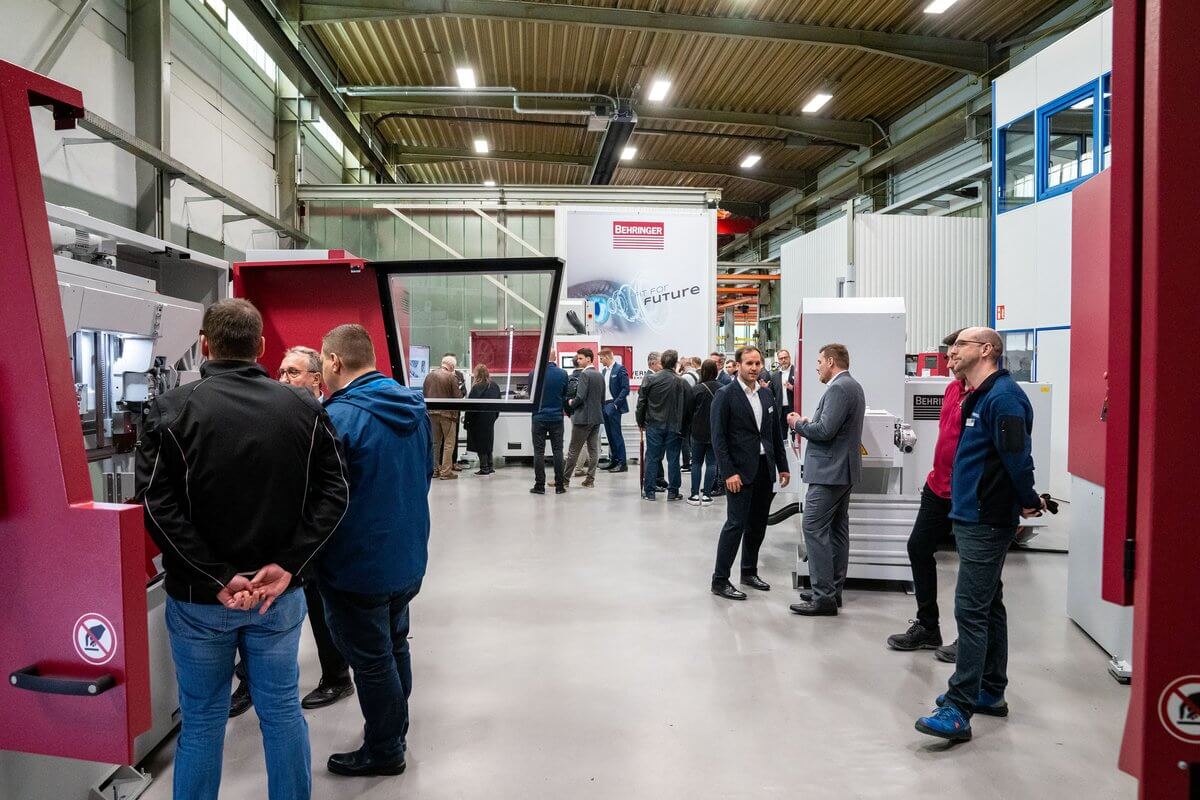

After the ninth edition of the Behringer in-house exhibition, Managing Director Christian Behringer draws an extremely positive conclusion. "Our visitors were enthusiastic and actively exchanged ideas with the experts on site," reflects Christian Behringer, recalling numerous conversations. The in-house exhibition was an impressive experience for everyone involved. In 2003, BEHRINGER laid the foundation for the event and invited visitors to the "World of Sawing Experience". Since then, the Behringer Group has developed further and expanded its portfolio to include sheet metal and profile machining centres. Under a new name, "Steeldays" now presents the wide range of innovative machines and solutions for efficient manufacturing.

For more than 700 guests from 25 nations, the three-day event offered a platform for discussion, knowledge and experience exchange. The participants took the opportunity to learn about current industry trends, new machine and plant systems as well as interface and software solutions. Exciting guest contributions and keynote speeches as well as the presentation of the new control interface complemented the offer.

New control unit presented

The presentation of the new BehrCtrl10 machine control system was a strong visitor magnet. In cooperation with the control manufacturer Siemens, a uniform control concept for band and circular sawing machines was created. "During development, we clearly focused on ease of operation. Thanks to our new auto-feed control with extensive material and tool database, the sawing machine independently sets the appropriate technology parameters," says Christian Behringer.

Automated material handling of aluminium ingots and AGV connection

In the aluminium theme area, a fully automated sawing and processing solution for handling continuous aluminium castings with an initial length of seven metres was presented. Here, the ingots are sawn to section lengths of one metre, the first cuts are disposed of and transported via a transfer line to an automatic lathe. A gripper then transports the peeled ingots into an ultrasonic basin and places them on pallets. Depending on the material diameter, the cut-offs weigh around one tonne. The roller conveyors, cross conveyors and gripper systems are designed to be correspondingly massive and robust.

The automatic aluminium circular saws from Behringer Eisele enable cuts every second. The VA-L 560 NC3 XL can cut diameters of up to 240 millimetres at high speed and still conserve resources. This is because the residual piece length is just 50 millimetres. Coupled to the automatic aluminium circular saw, exhibitor JTA Connection from Finland demonstrated a driverless transport system with a robot cell. The AGV picked up the box with the sawn aluminium pieces at the automatic circular saw and transported them to the cell, where the robot removed the sections individually from the AGV.

Interlinked processing solutions for steel construction and steel trade

Automated processing plays a major role in the steel trade and steel construction. Steel beams, profiles and angles are prepared for further processing steps, such as drilling holes and threads, milling slotted holes or marking the material. These operations are predestined for the HDS and HDX machining centres from Vernet Behringer. The workpieces are machined simultaneously by up to four axes that can move independently of each other. In combination with a band saw from Behringer, the profiles are sawn to final size after machining.

Since its market launch, the HDX profile machining centre from Vernet Behringer has focused on speed and energy efficiency. Compared to comparable machines, the HDX offers the same or better machining performance with significantly lower power consumption. The 6-pole spindle motors used in combination with a 1:2 transmission ratio between motor and drilling axes enable high spindle torque at lower power.

Large bandsaws

The visitors were impressed by the exhibited large band saw in GANTRY design with two saw heads. The enormous dimensions of 4.40 m height, a width of 8 m and the 24 m long material table indicated that the saw is designed for large and heavy workpieces. Thanks to its two sawing units, the long material table can be flexibly loaded and the saws can work unattended for a long time. The centrally positioned material support table is recessed in the foundation and can therefore support even the heaviest loads. The GANTRY saw is often used in forging plants, foundries and steel processing.

Workshop saws

Smaller saws for single cuts and rooms with limited space were also exhibited. The circular saws of the VMS and PSU series from Behringer Eisele are suitable for smaller diameters as well as trial and single cuts with materials that are difficult to machine. The HBE320-523G mitre band saw also impressed as an all-rounder. Supplemented with handy transport and measuring systems, the saw is suitable for mitre cuts of beams and solid materials.

Sustainable iron casting from Germany

The tour of the in-house and modern iron foundry was also highly frequented. In the block moulding plant, production is semi-automated with unit weights of up to 200 kilos. Large castings weighing up to 2 tonnes on average are produced in the hand moulding shop. 40 percent of the parts produced are used in the company's own sawing machines. Orders from regional customers account for about 60 per cent of the capacity utilisation.

Saws for plates and blocks

With the two automatic plate saws LPS25-200-6A and LPS40-160-4A, Behringer presented the ideal solution for the fully automatic cutting of plates into parts. The 90° rotatable band guide enables the sawing of finished parts in one clamping. The panel editor visualises the sawing tasks very clearly. This avoids errors in advance and reduces waste. The nesting functionality of the vertical bandsaw reduces processing time and waste.

Partners present their service portfolio

In addition to the Behringer Group as the main exhibitor, other companies participated in the Steeldays with machines, systems and information stands. RÖSLER GmbH from Untermerzbach provided information on their innovative solutions for surface processing. Together with Behringer and Vernet Behringer, the companies form the alliance "PARTNERS 4 STEEL" (P4S) with integrated process solutions for digitalised steel construction and steel trading.

Another highlight of the exhibition was the used machine MAG EVO from Vernet Behringer, presented by the company NENOK from Cologne. The panel processing centre is one of the most modern on the market. Equipped with the latest drilling and milling tools as well as a plasma cutting system, visitors were able to see for themselves the performance, precision and speed of the system for processing sheet metal.

To remove the burrs from the workpieces in the downstream step, SPALECK Industries demonstrated the use of a drum deburring machine. The cut-out parts are placed in the drum together with an abrasive granulate. The rotating movement removes the burrs and improves the surface quality.