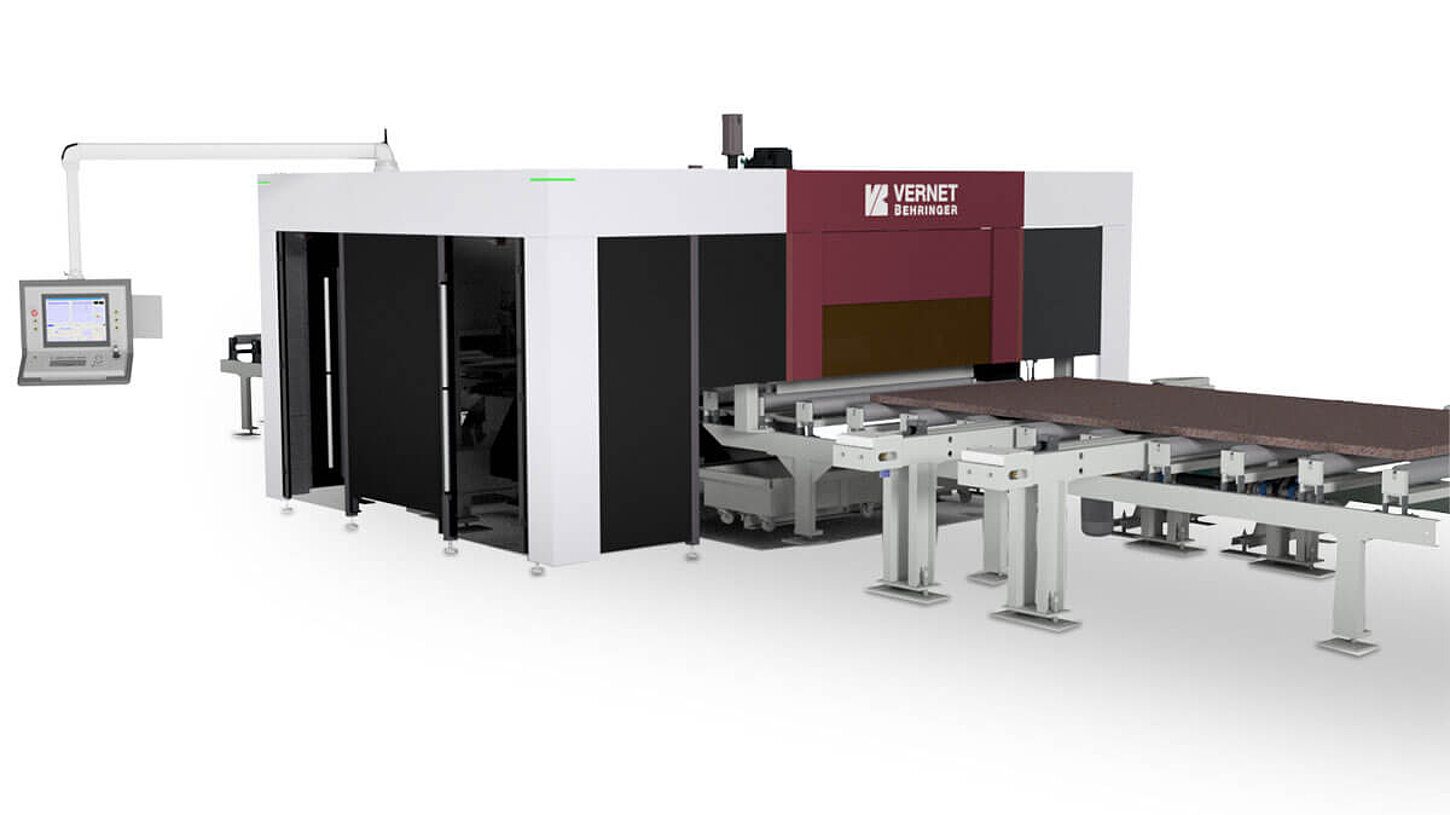

MAG620 - Plate machining centre

Drilling, milling, marking and plasma cutting for plates with one single reference

The Vernet Behringer MAG620 plate machining machine offers precise and fast machining in a passthrough operation. It combines marking, carbide drilling and milling, holes deburring (lower and upper faces) and high definition plasma cutting (straight and bevel cuts).

The MAG620 also offers a high level of automation with automatic part handling and automatic or semi-automatic plate loading.

| Marking | |

| V-scoring fast marking | Standard |

| High speed disk marking unit with 40 characters | Option |

| Drilling | |

| Spindle power | 16 kW |

| Rotation speed | 160 - 4,000 rpm |

| Maximum drill diameter | 50 mm Ø |

| Tool changer | 14 stations |

| Plasma cutting | |

| Plasma source | Hypertherm - Kjellberg 170 - 400 A |

| Machine Control | PROSH programming software with nesting license |